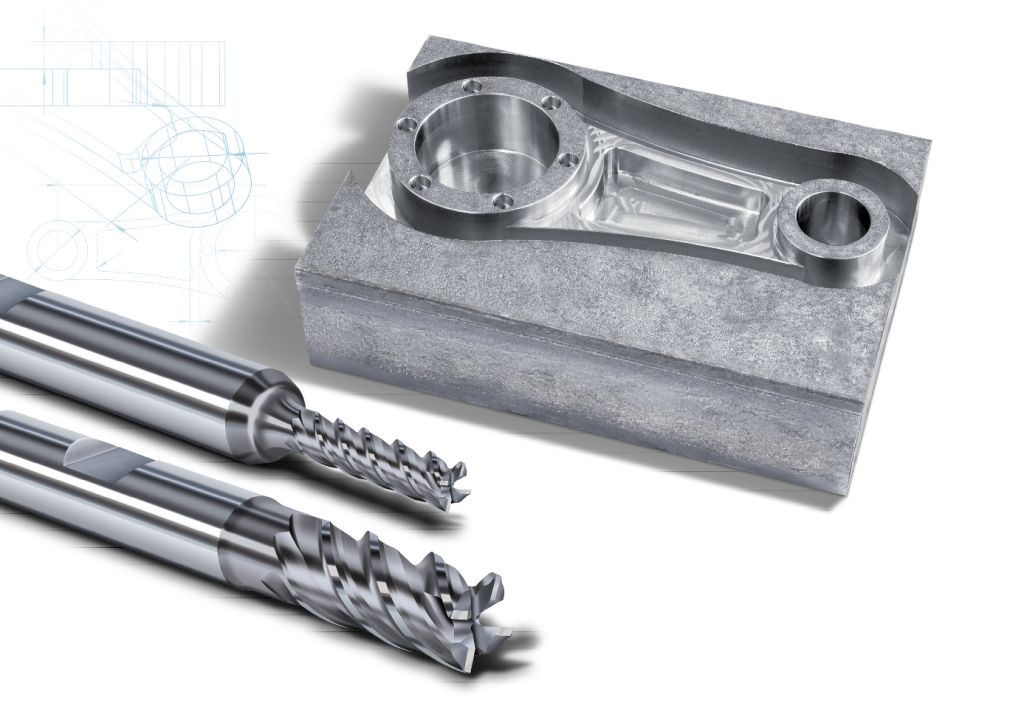

FRAISA SteelCut – Process-safe milling of soft steel at the highest level

11.08.2025

Whether mild steel, quality steel or heat-treated steel - the many types of mostly unalloyed or low-alloy materials are demanding and difficult to machine. They have a ductile and at the same time inhomogeneous microstructure and generate unpredictable wear during machining.

The materials are usually formed, joined or reworked by forging. As a result, the residual stresses are not evenly distributed, which poses an additional challenge during machining. The areas of structural steel, unalloyed quality steel, heat-resistant steel, unalloyed engineering steel and fine-grained structural steel alone already comprise 150 different materials.

FRAISA has developed the new SteelCut milling system with a very broad material coverage and robust behavioral characteristics in order to be able to machine mild steel reliably and efficiently. Depending on the material, there are different requirements within the same machining class - many tools can only cover a very small range of applications in the material class Rm < 850 N/mm2. This is precisely where the SteelCut proves its strengths by opening up completely new application horizons.

Photo: FRAISA

Not all mild steels are the same

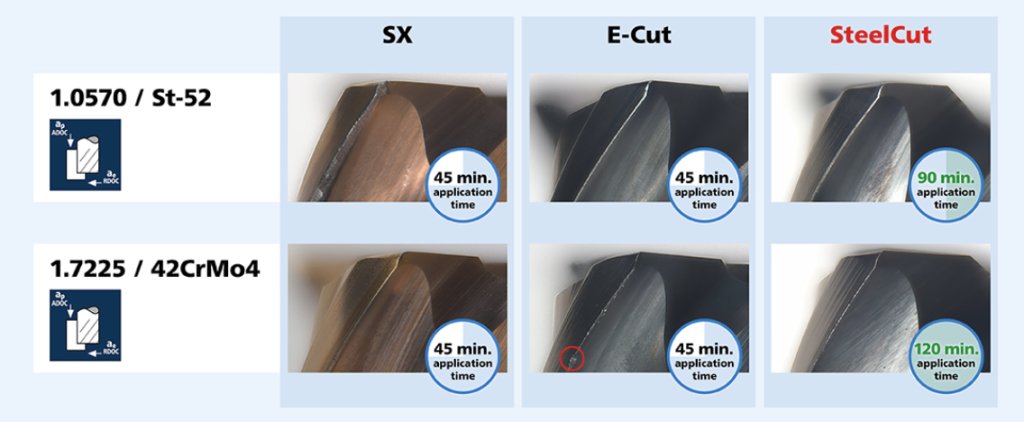

Within the mild steel material group, structural steel St-52 / 1.0570 and heat-treated steel 42CrMo4 / 1.7225, for example, exhibit completely different wear behavior in wet machining (emulsion) with the same application data. The task for the FRAISA engineers was to develop a consistently efficient system that could master the following challenges when milling mild steel:

Formation of built-up edges: Due to the low hardness of mild steel, material can build up on the cutting edge, which can lead to poor surface quality and tool wear.

Solution: The use of coated tools and high cutting speeds.

Chip removal:Mild steel tends to produce long, cohesive chips that can block the milling path.

Solution: Optimization of the tool geometry for optimum chip formation and chip evacuation.

Heat generation:

High cutting speeds can lead to excessive heating of the workpiece and the tool, which can cause dimensional inaccuracies.

Solution: The correct choice of cutting parameters, e.g. from the FRAISA ToolExpert®.

Oscillations (vibrations):Long tool overhangs can cause vibrations, which can lead to poor dimensional accuracy and tool wear.

Solution: More stable clamping, smaller infeeds and the use of milling cutters with variable cutting edge spacing.

The SteelCut milling system was specially developed for machining soft steels and scores with excellent tool life, high process reliability combined with silky-smooth running and optimum chip evacuation. The SteelCut unfolds its full potential in both dry and wet machining with emulsion or oil and delivers outstanding results.

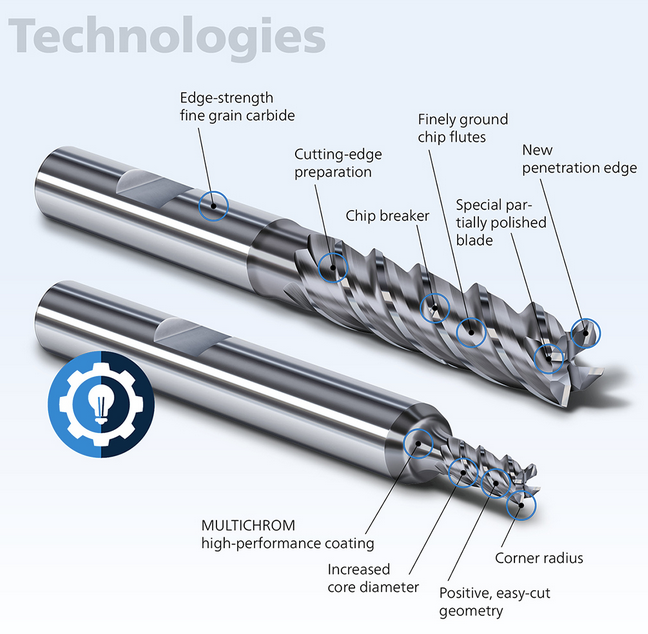

The newly developed hard and very smooth MULTICHROM high-performance coating has a positive effect on service life and guarantees an increased metal removal rate during milling and plunging. The high-performance milling cutters can be used universally and cover both HPC and HDC processes.

Photo: FRAISA

Material of the milling cutter:

- Edge-resistant ultra-fine grain carbide for plunge, HPC, HDC and finish machining and long tool life

Coating:

- High-performance MULTICHROM coating for maximum process reliability and low material adhesion

- Low sticking tendency, prevention of adhesion and built-up edge formation

- High wear resistance even under high thermal loads

- High-precision coating thickness distribution, maximum tool precision

Geometry:

- Chip breaker system for better chip evacuation

- Positive rake angle for a soft, light cut to prevent chips from jamming

- Tooth grinding reduces cutting forces, improves chip evacuation and reduces tool wear

- Plunge face enables smooth and low-vibration plunging

- Corner radius for better tool life and surface quality

SteelCut - the reliable all-rounder for maximum performance and tool life

FRAISA carries out extensive tests in order to keep an eye on the state of tool and application technology at all times. The tools are tested in different materials with various milling strategies. The focus was on HPC milling, plunging and HDC milling, as these involve particularly high mechanical and thermal loads. These tests ensure that the tools cover a wide range of materials and applications while guaranteeing maximum performance and service life.

The following wear images are impressive proof of this:

Photo: FRAISA

Advantages of the SteelCut milling system:

Perfect for plunging, HPC, HDC and finishing

Broad application and material range

Optimal chip formation and good chip removal

Perfect application data in the FRAISA ToolExpert®

High tool stability and resistance

Sustainable service offers with FRAISA ReTool®Services

Application advice and optimum cutting data for mild steel milling

In addition to the SteelCut milling tools, FRAISA also provides valuable application knowledge for correct machining. FRAISA application engineers advise our customers on all questions relating to the next machining challenge, e.g:

In addition, FRAISA invests a large proportion of its development costs in the preparation of tool- and material-specific cutting data, which is tested under real conditions in the FRAISA application centers.

The result is high-precision application parameters that are bundled in the FRAISA ToolExpert® online cutting data calculator and can be called up quickly and easily at any time. The integration of online interfaces also enables direct import into the CAM or TDM system - compared to manual input, this significantly reduces the time required and susceptibility to errors.

Source:

www.fraisa.com

www.mb-naklo.si