Economical drilling done smart

04.12.2025

The secret to the success of the machining company.

Zerspanungstechnik Mangner GmbH in Bad Laasphe, Germany, is targeted investment in optimisation. Drilling has been made more efficient thanks to a large tool package from MAPAL. The package is made up of 110 TTD replaceable head drills along with a big stock of solid carbide heads.

Photo: Migrated manufacturing in the area of drilling at the company Zerspanungstechnik Mangner GmbH entirely to MAPAL’s TTD replaceable head drill system (from left): Uwe Rein (Regional Sales Manager, MAPAL), Dominik Geßner (Production Manager, Mangner) and Mike Mangner (Managing Director, Mangner). ©MAPAL

When Mike Mangner started his company in a small rented hall in 2013, tools still had to be changed by hand. The young company developed quickly. Just one year later, the company bought its current and set up the first Hermle machines. As a traditional contract manufacturer, most of Mangner’s customers come from the tool and mouldmaking industry. The company offers them services like pressure die casting, sand casting and modelmaking. Most of the work is destined for the automotive industry. Besides this, parts are also produced for general machine engineering. Mangner’s customers come from all over Germany, but above all from their region.

In the meanwhile, 15 machining centres can be found on their shop floor, above all from Hermle. From the smallest 5-axis machine to the machining centre for components as large as 1 x 1 m, they cover a wide spectrum of components. There are about two machines for every operator. Programming takes place directly at their workplaces. Mike Mangner’s optimisation philosophy involves having many identical machines in operation. A next step in the standardisation process involves making available as many of the same tools as possible for these machines. ‘With this concept, we are in a strong position and can employ our operators flexibly’, Mike Mangner explains.

Photo: Mangner mostly uses Hermle machining centres for manufacturing. Programming takes place directly at the machine. ©MAPAL

Hirth serration from MAPAL enables high torque

Dominik Geßner switched to Mangner as a production manager two years ago, bringing along his experience and contacts. MAPAL and their Regional Sales Manager Uwe Rein was among them. Geßner advocated the use of TTD replaceable head drills, which he had come to know and appreciate over the years.

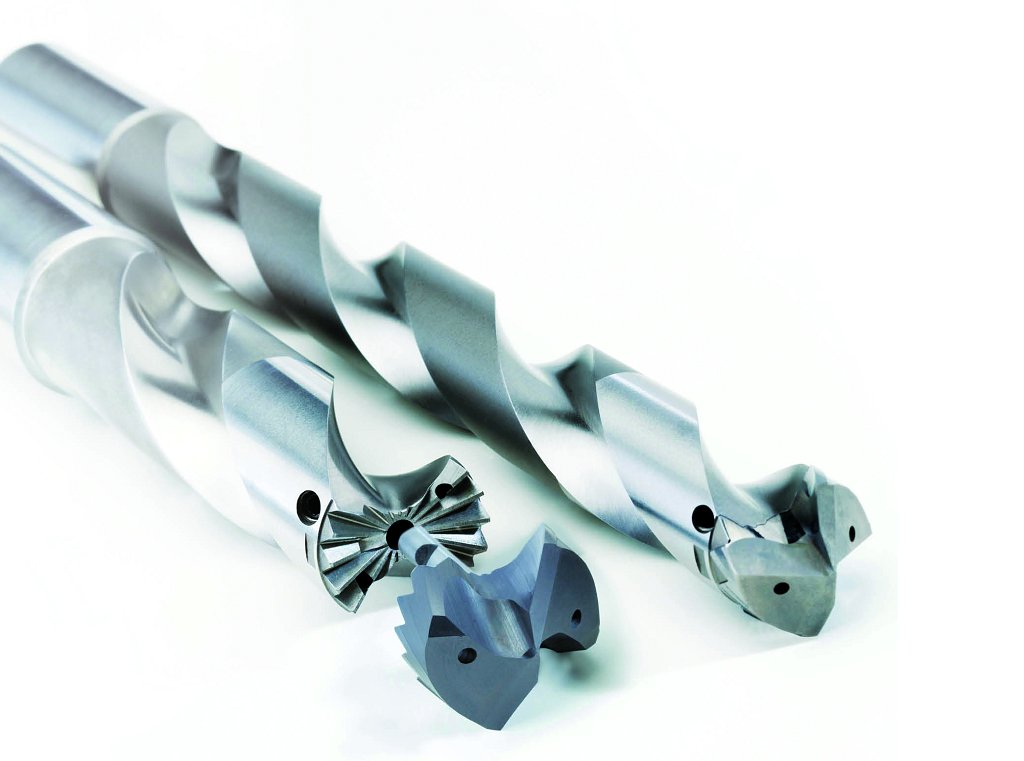

The TTD replaceable head drill is the primary application for the TTS (Torque Transfer System) interface. The interface owes its stability to the radially arranged Hirth serration with 12 or 18 teeth, depending on the diameter of the adapted solid-carbide drill head being used. Due to the serration’s form closure, variable geometries of the replaceable head are possible. In addition, optimal torque transfer and high radial run-out and change-over accuracy are ensured.

The replaceable drill head is secured by a threaded pin affixed to the side of the tool holder. This allows the drill bit to be changed directly in the machine. The positioning aid integrated in the serration ensures that the chip flutes and coolant transfer from the tool holder to the replaceable drill head match. With its cutting-edge geometry, the drill head has a quality and performance level similar to solid carbide drills.

Photo: Examining the drill head of a TTD tool (from left): Dominik Geßner (Production Manager, Mangner), Uwe Rein (Regional Sales Manager, MAPAL), Mario Schäfer, (Assistant Production Manager, Mangner) and Mike Mangner (Managing Director, Mangner). ©MAPAL

Machining time reduced

‘The true advantage of these drills comes into play in hardened materials, which it can machine reliably’, Geßner reports. ‘We achieve a long tool life here, which reduces our throughput of drill bits.’ At Mangner, bores used to take place prior to hardening. By eliminating the need for an additional clamping step, set-up time has been reduced. This increases efficiency in manufacturing, thereby providing the company with added value.

The previously used tool system had a particular weak point: if a solid-carbide drill head broke off, the drill bit holder was usually also damaged. In Geßner’s experience, this has never happened with MAPAL. After breakage, work could always continue with a new drill head, limiting any resulting damage. ‘I primarily considered changing the tool system from a cost perspective’, says Mike Mangner, explaining why he chose MAPAL.

Photo: The large tool package from MAPAL for Mangner includes a total of 110 TTD replaceable head drills with diameters from 12 to 45 mm and lengths of up to 12xD. ©MAPAL

More economical and sustainable

Mangner uses the drills above all to pilot deep bores as well as complete bores for cooling, so-called coolant boost. While the normal lead geometry of the cutting edge is 140°, MAPAL also offers variants for special applications. A 180° tip can execute countersink bores, for example, which would otherwise only be possible with a milling cutter. Ball-nose drills enable radii at the end. Geßner reports that if handled with care, the drill heads can be reground up to three times by MAPAL. ‘This is very sustainable and lowers the average price per tool.’

The tool package delivered by MAPAL includes diameters from 12 to 45 mm, whereby the tool lengths are 3xD, 5xD, 8xD and 12xD. ‘We cover a certain diameter range with replacement head drills in increments of tenths’, Geßner specifies. ‘The tools would be unaffordable with drills made entirely of solid carbide.’ The many sizes reflect the various requirements of manufacturing. Series of up to 100 parts are rare here. Typical lot sizes are between one and 10 pieces. The material is often heat-resistant 1.2343 steel, but special materials, steel with varying degrees of hardness and aluminium are also processed.

After the successful deployment of TTD drills, the cooperation between Mangner and MAPAL is set to continue. Reamers are already in use. Test finishing with milling cutters is also taking place. Uwe Rein thinks that high-feed cutting could be the next step.

Photo: The Hirth serration of the TTD drill from MAPAL ensures the drill heads sit very securely. This enables optimal torque transfer as well as high changeover and radial run-out accuracies. ©MAPAL

Source: MAPAL