Tungaloy extends TungMeister with R0.2 corner radius solution

26.01.2026

With a new R0.2 corner radius square head, Tungaloy Corporation extends its Tungmeister range to meet growing demand for very small corner radii. The solution combines solid end mill–level precision with the flexibility, efficiency and reduced setup times of an exchangeable-head system for precision parts and mould machining.

Tungaloy Corporation has expanded its Tungmeister portfolio with the introduction of a square head featuring a corner radius of R0.2. The new head is designed to deliver solid end mill–level precision while retaining the flexibility and productivity benefits of an exchangeable-head system, particularly for the machining of precision components and moulds.

In precision component and mould manufacturing, drawings increasingly specify very small corner radii of R0.3 or less. Until now, conventional Tungmeister square heads with a minimum corner radius of R0.5 could not meet these requirements, often forcing users to switch to solid end mills. While capable of achieving small radii, solid tools typically involve higher costs and lower overall efficiency. As a result, demand has grown for exchangeable-head solutions that combine fine-detail machining with productivity and cost advantages.

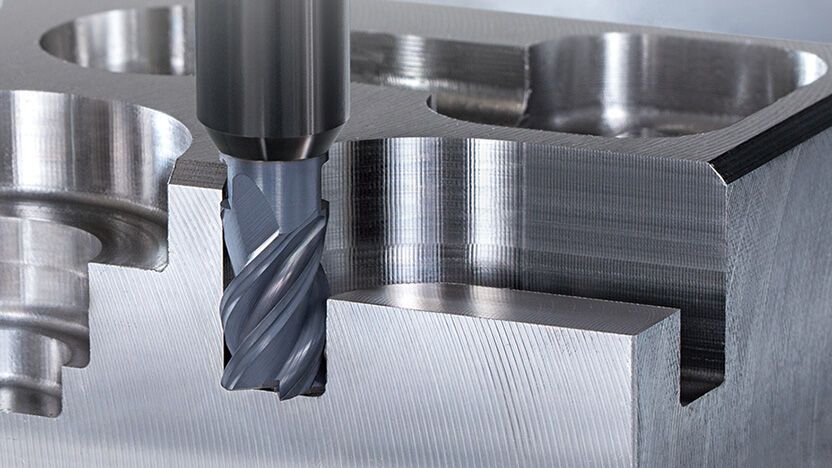

Photo: The new R0.2 corner radius square head expands Tungmeister from Tungaloy Corporation, enabling high-precision machining with exchangeable-head flexibility.

Source: Tungaloy

Tungmeister is Tungaloy’s high-efficiency exchangeable-head end mill system. With more than 45 head geometries and a wide selection of shank materials, the platform covers a broad range of machining applications. The exchangeable-head concept allows quick tool changes, reducing setup time while maintaining high levels of accuracy and productivity.

High-precision machining with R0.2 corner radius

The newly added R0.2 corner radius head enables machining of components with drawing specifications requiring corner radii of R0.3 or smaller. This allows small-radius corner machining with an exchangeable-head tool, offering an alternative to solid end mills for applications demanding fine detail, such as precision parts and moulds.

The separable design of cutting head and shank enables rapid tool replacement without the need to re-adjust tool overhang length. This reduces machine downtime while ensuring stable repeatability and consistent machining accuracy after head changes.

An enlarged shank diameter improves overall tool rigidity. Adjustable overhang lengths allow machining conditions to be optimised for specific applications, helping to suppress chatter and support stable machining even under high-feed or deeper cutting conditions.

Published on: www.etmm-online.com

Source: Tungaloy